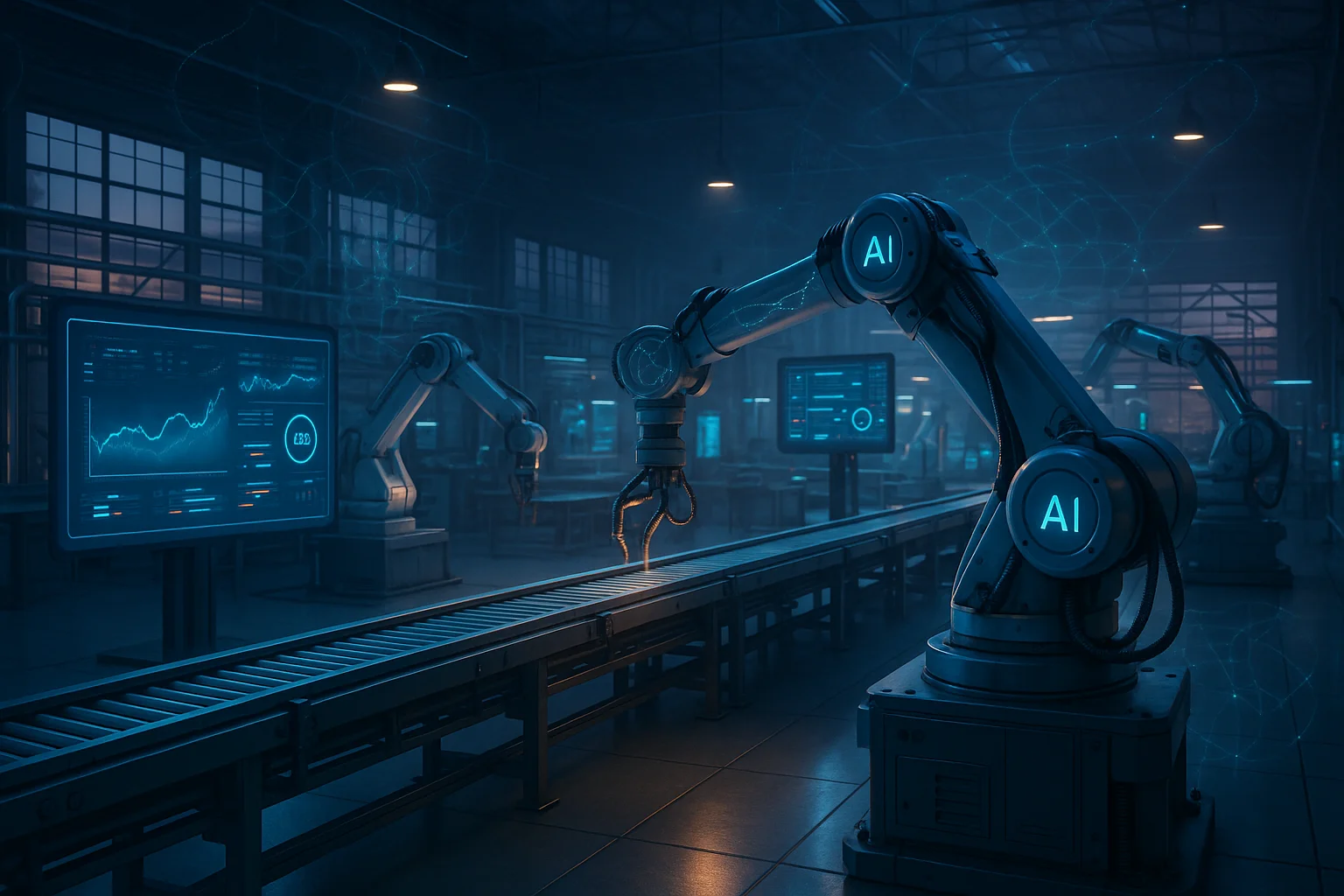

Factories don’t sleep anymore — they think. Every minute of downtime costs money, efficiency, and opportunity. In today’s manufacturing world, where precision and speed define survival, artificial intelligence has quietly become the secret weapon powering the industry’s next big leap.

Factories don’t sleep anymore — they think. Every minute of downtime costs money, efficiency, and opportunity. In today’s manufacturing world, where precision and speed define survival, artificial intelligence has quietly become the secret weapon powering the industry’s next big leap.

AI in manufacturing is quietly transforming shop floors into intelligent, connected ecosystems. Machines can now sense when something’s about to go wrong, adjust performance in real time, and even suggest better ways to operate. From predictive maintenance to real-time quality checks, factories are no longer reacting to problems — they’re preventing them before they start.

This isn’t just about automation — it’s about intelligence. AI helps factories make smarter decisions every second, turning raw data into insights that drive real action. Whether it’s predictive maintenance, quality control, or generative design, manufacturers embracing AI are running leaner, safer, and far more efficiently than ever before.

What Is AI in Manufacturing?

At its core, AI in manufacturing refers to the application of artificial intelligence — machine learning, computer vision, predictive analytics, reinforcement learning, generative models, agents — within production systems. The goal: to make factories smarter, more resilient, and more efficient.

Key variants include:

Generative AI in manufacturing — e.g. AI systems that design part geometries or simulate process flows.

Agentic AI in manufacturing — autonomous agents that monitor, decide, and act in operations (e.g. scheduling agents, self-optimizing controllers).

AI is not a replacement of machines — it’s the intelligence layer above them. It turns raw sensor signals, logs, and process data into proactive decisions.

Why ROI & Downtime Should Be Your Focus

It’s one thing to experiment, but to win strategically, you need business impact. Two metrics tend to matter most:

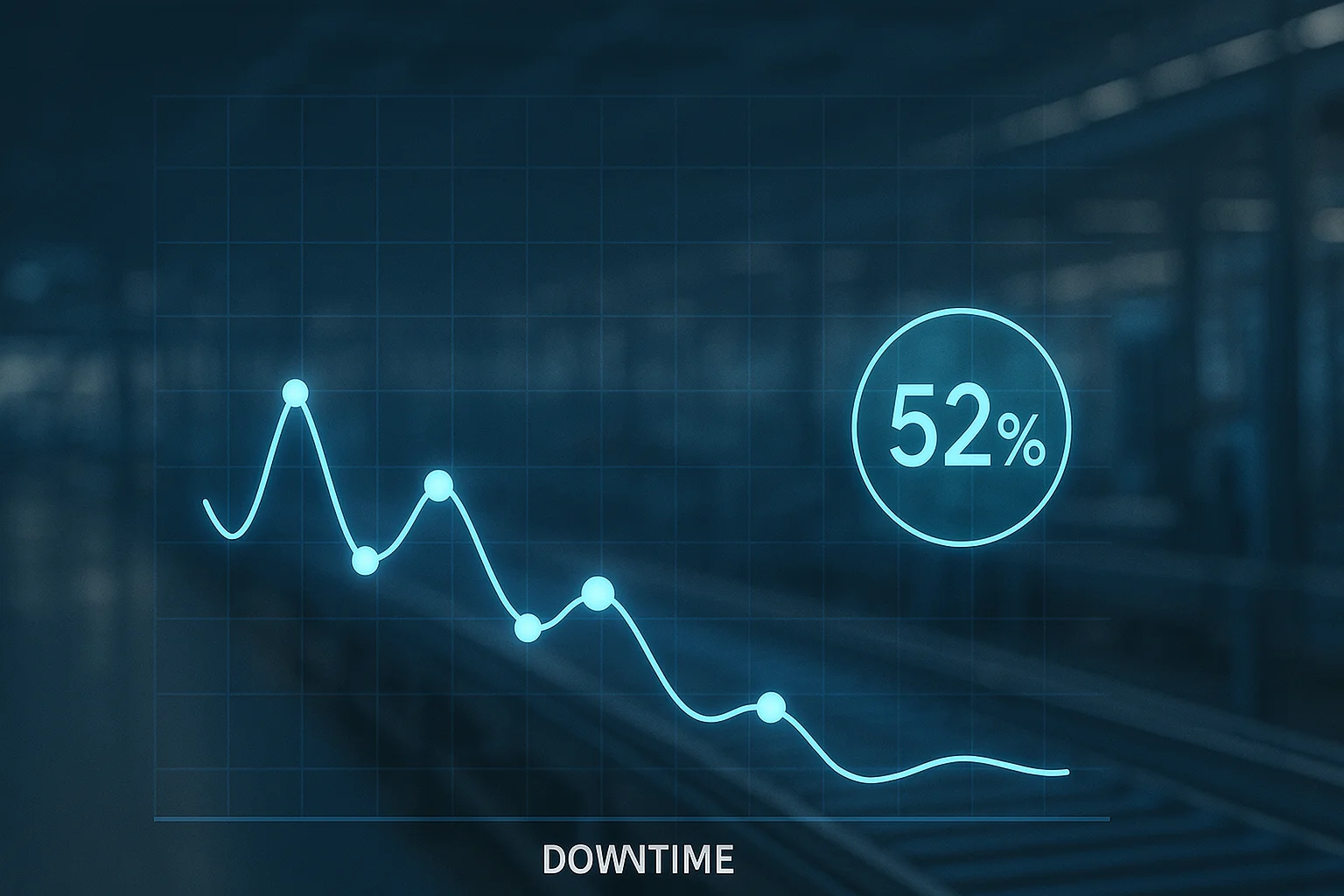

Downtime / unplanned stoppages — idle lines = lost revenue.

Return on Investment (ROI) — you need to prove the dollars (or rupees) coming back from your AI investment.A few eye-opening data points:

AI-driven predictive maintenance can reduce unplanned downtime by up to 50%, and cut maintenance costs by 10–40%.

- A case study in food manufacturing recovered US$0.5M/week and boosted output by 5% through AI.

- A U.S. aluminum manufacturer realized US$5.3M ROI in just 30 days after shifting from reactive to predictive maintenance.

- AI investments generally produce returns within 12–18 months, when deployed properly.

- According to IDC / Microsoft data, for every $1 spent on AI, companies realize on average $3.50 in return.

These numbers make a clear case: AI isn’t just a gadget — it’s a lever for operational and financial transformation.

Core Applications of AI in Manufacturing

Here are the main domains where AI is already making waves:

| Application | What It Does | Business Impact | Example / Notes |

|---|---|---|---|

| Predictive Maintenance | Monitors sensor data, detects anomalies early | Fewer breakdowns, longer asset life, lower repair costs | Festo’s AI predictive tool saved ~$16,000 per machine by early detection. |

| Quality Control & Inspection | Uses computer vision, anomaly detection on product lines | Lower defect rate, less scrap, improved yield | BMW uses AI to detect body panel defects in real time. |

| Supply Chain & Demand Forecasting | Predicts demand, optimizes inventory & logistics | Reduced stockouts, minimized wastage | Siemens uses AI to align demand across factories. |

| Energy & Resource Optimization | Models energy use, adjusts operations dynamically | Lower energy bills, greener operations | Schneider Electric’s energy AI optimizes facility usage. |

| Generative Design & Simulation | Creates new designs, simulates processes in silico | Faster innovation, material savings | Airbus uses generative design for lighter parts |

| Agentic AI / Autonomous Agents | Self-optimizing systems, scheduling agents, control loops | Reduced human micromanagement, continuous tuning | Agents can autonomously shift line parameters or reroute flows |

You see how many of those connect directly to cutting downtime or improving ROI.

Real-World Examples & Case Studies

Here are a few standout illustrations:

Food Manufacturing Case: A global food & beverage company used ThroughPut’s AI platform to eliminate unplanned outages, recover US$0.5M weekly, and increase output by 5%.

Aluminum Production Case: After applying predictive AI, a U.S. aluminum plant achieved US$5.3M of savings in 30 days.

Festo Predictive Maintenance: The Festo AX solution optimized a machine tool application, catching anomalies before failure and saving ~$16,000 per machine.

General Motors: GM implemented AI for predictive maintenance to reduce factory downtime — indicative of how large players adopt these systems.

Global Lighthouse Factories: In McKinsey’s “Lighthouse” network (leading 4IR factories), AI use cases make up over 60% of new transformation projects.

These stories prove AI isn’t just theoretical — it’s delivering hard outcomes.

Generative & Agentic AI: The Next Frontier

While classic AI and ML handle prediction and detection, generative and agentic approaches are pushing the envelope further:

Generative AI in manufacturing can design new parts, simulate process variations, or generate synthetic data for training quality systems.

Agentic AI in manufacturing means autonomous agents that continuously monitor, adapt, and act — for example, an agent could reroute production flows or adapt preventive maintenance schedules in real time.

McKinsey calls agentic AI a productivity lever, estimating modest gains (5–10%) initially, with potential to grow as systems mature.

Generative AI more broadly is estimated to add $2.6−4.4 trillion annually across industries.

These technologies bridge the gap between analysis and autonomous execution.

Benefits & ROI Beyond Downtime

AI in manufacturing brings far more than just automation. It transforms how factories think, learn, and perform every day.

Better throughput and utilization

Machines operate closer to full capacity with fewer slowdowns or idle times — squeezing the most value out of every minute.Higher consistency and quality

AI catches defects before they become costly problems, ensuring products meet the same high standards from the first unit to the millionth.Lower energy use and waste

Smart algorithms fine-tune energy consumption, reducing waste while keeping production smooth and sustainable.Faster product innovation and design cycles

Generative AI helps engineers test thousands of design variations virtually, cutting months off R&D time.Stronger supply chain resilience

With predictive analytics, companies can see disruptions coming — and act before they hit.Smarter capital investment decisions (CAPEX)

AI reveals where upgrades truly pay off, guiding smarter spending on machines, tools, and tech.

Challenges of AI in Manufacturing

Even the most advanced technology faces real-world roadblocks. The key is to spot them early and plan around them.

Poor data quality or missing sensors

AI is only as good as the data it learns from — incomplete or messy data can distort results.Legacy systems and integration complexity

Old machines often struggle to “talk” to modern AI systems, making integration a slow and costly process.Skill gaps and unwillingness to change

Many teams need upskilling to trust and operate AI tools effectively. Change management is just as important as tech adoption.Unclear ROI or lack of buy-in

Without early wins or visible metrics, leadership support can fade — killing momentum before results appear.Overambitious pilots that never scale

Many projects start big and stall fast. The secret is to start small, prove value, and scale carefully.

Future of AI in Manufacturing

The factories of tomorrow won’t just run faster — they’ll think, predict, and evolve continuously.

Self-optimizing agentic factories

AI agents will independently manage production flows, making real-time decisions to keep everything on track.Digital twins and real-time simulation

Every machine and process will have a virtual replica — letting manufacturers test, tweak, and train before making real-world changes.Augmented reality and AI for maintenance

Technicians will wear AR glasses that guide them step by step — powered by AI diagnostics behind the scenes.Tighter AI-IoT convergence

Connected sensors will stream nonstop data into AI models, turning every part of the factory into a source of insight.Generative design for everyday engineering

Engineers will rely on AI co-designers to create stronger, lighter, and more cost-efficient components.Cross-site federated learning

Factories will share model knowledge — not raw data — learning collectively without compromising security.

Future of AI in Manufacturing

AI in manufacturing isn’t a distant vision anymore — it’s already reshaping production floors worldwide. The companies leading this change aren’t just automating; they’re building factories that think, adapt, and grow smarter with every shift.

At Techelix, we help manufacturers make that leap — combining deep AI expertise with practical, real-world engineering insight. Whether it’s predictive maintenance, generative design, or intelligent automation, our AI solutions are built to deliver measurable impact where it matters most.

If you’re exploring how AI can transform your operations, discover more about our work in the manufacturing industry and see how the future of intelligent production is already being built today.

Build custom AI solutions that deliver real business value

From strategy to deployment, we help you design, develop, and scale AI-powered software that solves complex problems and drives measurable outcomes.